First large-scale bioplastic production from non-edible biomass

The four-year EU-funded BioConSepT research project developed production processes based on non-edible biomass. In comparison to current processes for bioplastic production, they do not compete with food production and aim to be cheaper and more sustainable. The second generation biomass used includes non-edible oils and fats, as well as lignocellulose (wood and straw). These materials are transformed into intermediates like biobased polymers, resins, plasticisers, and solvents, which can be applied in bioplastic production. 29 European partners collaborated to successfully demonstrate production at an industry-relevant scale.

Progress from biomass to applications

The whole production chain, from feedstock to final applications, is reflected in this European collaborative project. Chemical, enzymatic, and microbial processes convert second-generation biomass (which cannot be used in food production) into valuable platform chemicals used, for example, in bioplastics. Robust enzymes and microorganisms, continuous processes, new bioreactors, and selective purification technologies were key factors in reducing production costs.

Large-scale production

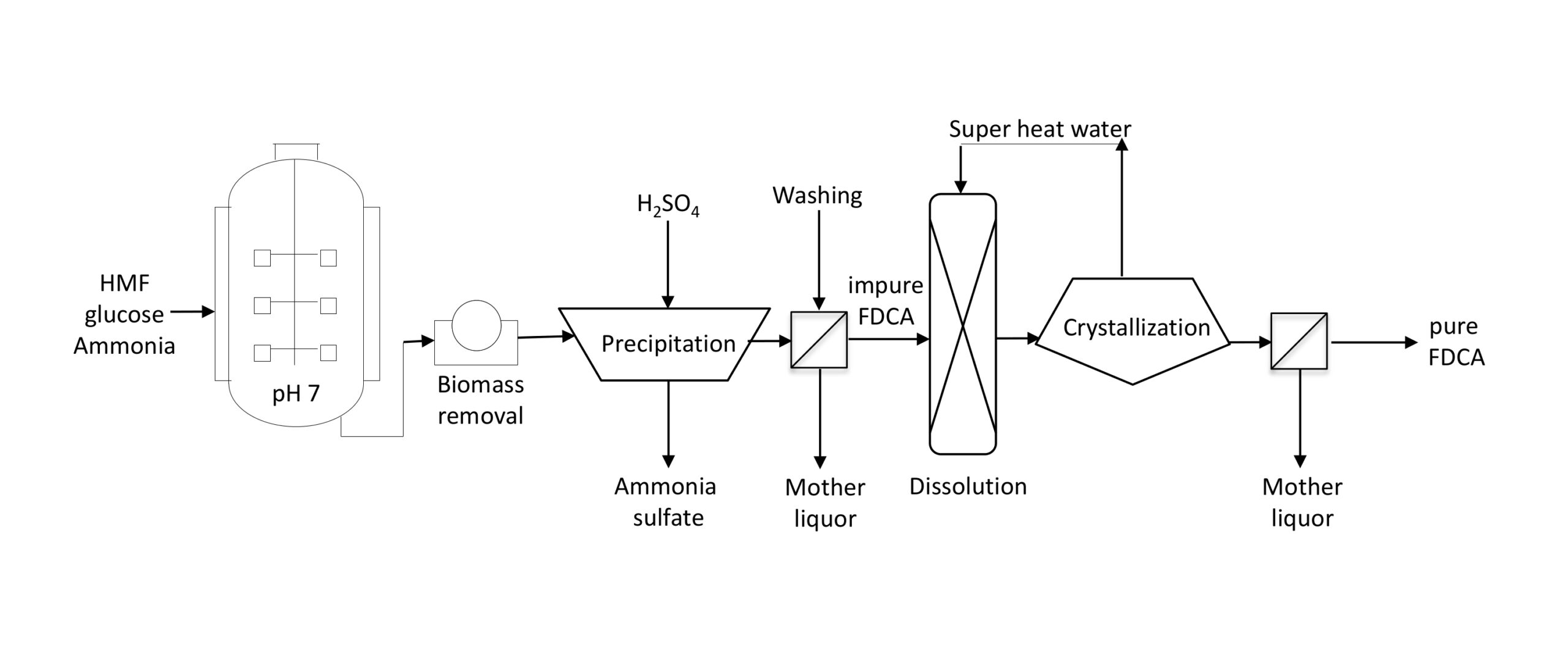

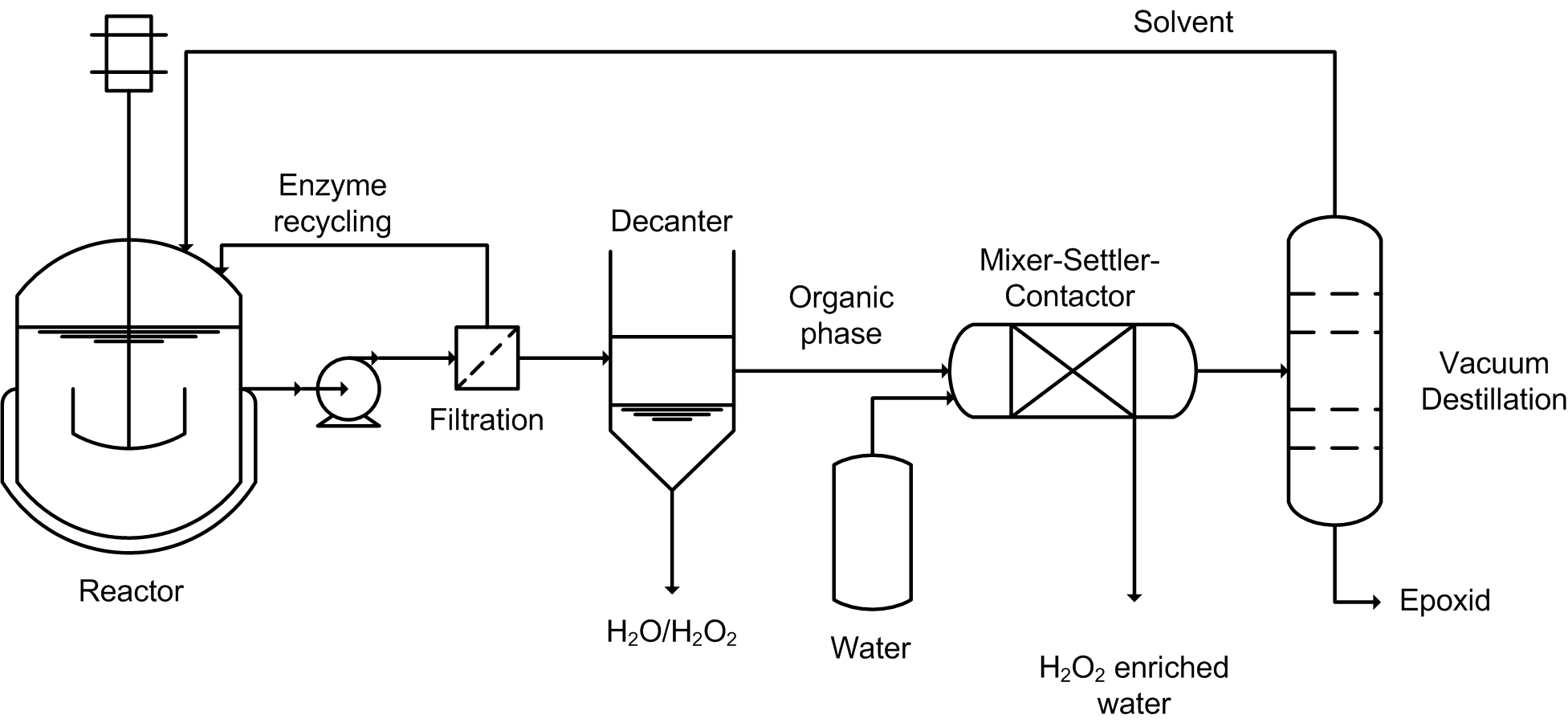

Upscaling of processes closes the gap from the lab to industrial production. The successful demonstration of the production of furandicarboxylic acid (FDCA) and epoxides in product-relevant amounts shows the potential of second-generation biomass. Bioreactors with up to 1 m³ produce about 100kg of both platform chemicals, which can be applied in packaging, textiles (as high-strength fibers), and coatings and adhesives.

Final conference in Merseburg, Germany

The consortium invited the international chemical industry to Merseburg, Germany, from 10th – 11th November to showcase BioConSepT results. The conference focused on the upscaling of the production of FDCA and enzymatic epoxidation to an industrially relevant scale. It included a visit to the piloting facilities of Fraunhofer CBP in Leuna, where some of the processing steps have been conducted. The consortium also presented the project’s most promising results from other bio-based chemical production chains.

About the BioConSepT project:

BioConSepT is a €13 Million EU-funded research project that converts second-generation biomass into valuable platform chemicals and bioplastics. This four-year project is coordinated by TNO and involves 29 partners from industry, research and technology organizations, and small and medium-sized enterprises.

Contact:

Daniela Fichtenbauer, Dissemination Manager

RTD Services e.U, Lerchengasse 25/2-3, 1080 Vienna, Austria

fichtenbauer@rtds-group.com

M: +43 664 8333567

T: +43 1 3231000

Dirk Verdoes, Coordinator BioConSepT

TNO – Netherlands Organization for Applied Scientific Research, Leeghwaterstraat 46, 2628 CA Delft, The Netherlands

dirk.verdoes@tno.nl

M: +31 65 1347967

http://www.bioconsept.eu